| Rem. |

Parameter |

Description |

Minimum |

Maximum |

Default |

Unit |

| S__ | | | Functions about storage | | | | |

| | St_ | | Functions about storage temperature | | | | |

| | | _t0 | storage room temperature | -55.0 | 145.0 | 12.0 | °C |

| | | _db | dead band | 0.0 | 50.0 | 0.0 | K |

| | | dbd | differential | 0.0 | 50.0 | 0.2 | K |

| | | _tH | safety maximum room temperature | -55.0 | 45.0 | 21.0 | °C |

| | | _tL | safety minimum room temperature | -55.0 | 45.0 | 10.0 | °C |

| | | _td | safety temperature differential | 0.0 | 50.0 | 0.2 | K |

| | | SMM | storage room humidity | 0.0 | 100.0 | 90.0 | % |

| | | SMd | differential | 0.0 | 50.0 | 5.0 | % |

| | SA_ | | Functions about air renew during storage | | | | |

| 1 | | | SAH | enable air renew during storage - reset timers | oFF | _on | oFF | / |

| | | dA6 | immediate delay before first air renew | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| | | dA7 | on-time duration in the air renew cycle | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| 2 | | | dA8 | period of air renew cycle | 0 | 194 4:20:15 | 12:00:00 | dd hh:mm:ss |

| | | SAh | enable forced air renew by keyboard short cut | oFF | _on | _on | / |

| | | dAF | forced air renew duration | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | SAo | start / stop forced air renew | oFF | _on | oFF | / |

| r__ | | | Functions about ripening | | | | |

| | rH_ | | Enable ripening functions and short cut | | | | |

| 3 | | | rrH | enable ripening functions - reset timers | oFF | _on | oFF | / |

| | | rrh | enable toggling between ripening and storage by keyboard short cut | oFF | _on | _on | / |

| | rt_ | | Functions about ripening temperature and humidity | | | | |

| | | _d0 | immediate delay before starting ripening | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| | | _t1 | ripening temperature nr. 1 | -55.0 | 45.0 | 16.5 | °C |

| | | _d1 | duration of temperature nr. 1 | 0 | 194 4:20:15 | 4 0:00:00 | dd hh:mm:ss |

| | | _t2 | ripening temperature nr. 2 | -55.0 | 45.0 | 15.5 | °C |

| | | _d2 | duration of temperature nr. 2 | 0 | 194 4:20:15 | 1 0:00:00 | dd hh:mm:ss |

| | | _t3 | ripening temperature nr. 3 | -55.0 | 45.0 | 14.5 | °C |

| | | _d3 | duration of temperature nr. 3 | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| | | _t4 | ripening temperature nr. 4 | -55.0 | 45.0 | 14.5 | °C |

| | | _d4 | duration of temperature nr. 4 | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| 4 | | | _t5 | ripening temperature nr. 5 | -55.0 | 45.0 | 14.5 | °C |

| | | rMM | ripening humidity | 0.0 | 100.0 | 90.0 | % |

| | | rMd | ripening humidity differential | 0.0 | 50.0 | 5.0 | % |

| | rY_ | | Functions about ethylene | | | | |

| 5 | | | rYH | enable ethylene injection - reset timers | oFF | _on | oFF | / |

| 6 | | | YYb | use ethylene probe to control injections | oFF | _on | oFF | / |

| | | rYY | ripening ethylene concentration | 0.0 | 99.0 | 25.0 | 10*ppm |

| | | rYd | ripening ethylene concentration differential | 0.0 | 99.0 | 5.0 | 10*ppm |

| 7 | | | dY0 | immediate delay before starting ripening | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| 8 | | | _tY | minimum temperature before injecting ethylene | -55.0 | 45.0 | 16.0 | °C |

| | | dY2 | first ethylene injection duration | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | _nY | number of following ethylene cycles of injection | 0 | 255 | 0 | / |

| 9 | | | dY3 | delay between first ethylene injections end and following cycles | 0 | 194 4:20:15 | 1 0:00:00 | dd hh:mm:ss |

| | | dY4 | on-time duration of following ethylene injection cycles | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| 10 | | | dY5 | period of following ethylene injection cycles | 0 | 194 4:20:15 | 12:00:00 | dd hh:mm:ss |

| | | rYh | enable forced ethylene injection by keyboard short cut | oFF | _on | _on | / |

| | | dYF | forced ethylene injection duration | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | rYo | start / stop forced ethylene injection | oFF | _on | oFF | / |

| 11 | | | rYA | first ethylene injection performed but air renew not yet | oFF | _on | oFF | / |

| | rA_ | | Functions about air renew during ripening | | | | |

| | | rAH | enable air renew cycles during ripening - reset timers | oFF | _on | oFF | / |

| | | _nA | number of air renew cycles | 0 | 99 | 8 | / |

| 9 | | | dA3 | delay between first ethylene injection end and first air renew end | 0 | 194 4:20:15 | 1 0:00:00 | dd hh:mm:ss |

| | | dA4 | on-time duration in the air renew cycle | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| 10 | | | dA5 | period of air renew cycle | 0 | 194 4:20:15 | 12:00:00 | dd hh:mm:ss |

| | | rAh | enable forced air renew by keyboard short cut | oFF | _on | _on | / |

| | | rAF | forced air renew duration | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | rAo | start / stop forced air renew | oFF | _on | oFF | / |

| n__ | | | Functions about fans | | | | |

| | nU_ | | Functions about depression fans | | | | |

| | | nUS | number of depression fans during storage | 0 | 3 | 2 | / |

| | | nUr | number of depression fans during ripening | 0 | 3 | 3 | / |

| | nE_ | | Functions about evaporator fans | | | | |

| | | nEH | force evaporator fans when refrigeration is off | oFF | _on | oFF | / |

| P__ | | | Functions about master preferences | | | | |

| | Pd_ | | Functions about network address | | | | |

| | | PdM | master address for global network communication | 0 | 254 | 1 | / |

| | | PdS | number of slaves connected to this master | 1 | 2 | 2 | / |

| | | Pd2 | number of auxiliary masters connected to this master | 0 | 2 | 2 | / |

| | Pg_ | | Functions about saving preferences | | | | |

| | | Pgg | save actual preferences as program 1 ... 99 | 1 | 99 | 1 | / |

| | Pj_ | | Functions about loading preferences | | | | |

| | | Pjh | enable preferences load by keyboard short-cut | oFF | _on | oFF | / |

| | | Pjj | load preferences as program 0 ... 99 (0 is factory setting) | 0 | 99 | 0 | / |

| | PO_ | | Output assignment | | | | |

| | | PO2 | assign out-2 relay to: 0=alarm / 1=humidifier | 0 | 1 | 1 | / |

| c__ | | | Functions about door and light | | | | |

| | cO_ | | Functions about door | | | | |

| 12 | | | cOh | enable door operation from keyboard | oFF | _on | _on | / |

| 13 | | | cOF | enable door flashing light in case of alarm | oFF | _on | _on | / |

| 14 | | | cOd | delay between pushing button and door opening or closure | 0 | 194 4:20:15 | 2 | dd hh:mm:ss |

| | | cOH | enable door automatic closure | oFF | _on | oFF | / |

| | | cCd | delay of door automatic closure | 0 | 194 4:20:15 | 30 | dd hh:mm:ss |

| | | cOU | enable depressure, refrigeration and other output when door is not closed | oFF | _on | oFF | / |

| | | cOY | enable door opening after first ethylene injection and before first air renew | oFF | _on | _on | / |

| | cI_ | | Functions about light | | | | |

| 15 | | | cIO | switch on the light during door operation | oFF | _on | _on | / |

| | | cIH | switch on the light when the door is open and off when closed | oFF | _on | _on | / |

| 16 | | | cIo | switch off the light automatically if it has been switched on from outside | oFF | _on | _on | / |

| | | cId | delay of light automatic switch off | 0 | 194 4:20:15 | 30 | dd hh:mm:ss |

| | cc_ | | Functions about curtain operation | | | | |

| 17 | | | cch | enable curtain operation from keyboard | oFF | _on | oFF | / |

| 18 | | | ccc | keyboard in curtain mode | oFF | _on | oFF | / |

| 15 | | | ccO | enable curtain operation when door is not open | oFF | _on | oFF | / |

| 15 | | | ccI | enable curtain operation when light is off | oFF | _on | oFF | / |

| v__ | | | Functions about electronic expansion valve | | | | |

| | vP_ | | Functions about electronic expansion valve preference | | | | |

| 19 | | | vPH | enable electronic expansion valve | oFF | _on | _on | / |

| | vt_ | | Functions about electronic expansion valve temperature | | | | |

| 20 | | | vtt | wanted overheating (similar to Danfoss thermostatic overheating spring regulation) | 0.0 | 99.0 | 8.0 | K |

| | | vtU | maximum pressure allowed in the suction line (similar to Danfoss MOP) | 0.0 | 30.0 | 10.0 | (gauge) bar |

| | vd_ | | Functions about electronic expansion valve timing | | | | |

| 21 | | | vd1 | on-off duty cycle duration | 0 | 194 4:20:15 | 8 | dd hh:mm:ss |

| 22 | | | vd2 | on duty cycle duration at refrigeration start (set to 0 for previous stop value) | 0 | 194 4:20:15 | 5 | dd hh:mm:ss |

| 23 | | | vdd | on duty cycle adaptation speed (low value for slow adaptation and small swinging) | 0 | 255 | 8 | / |

| b__ | | | Functions about probe calibration | | | | |

| | b1_ | | Probe nr. 1 | | | | |

| | | b1C | calibration offset | -9.0 | 9.0 | 0.0 | K |

| | | b1A | use probe to calculate product average temperature | oFF | _on | oFF | / |

| | | b1S | use probe for safety temperature | oFF | _on | _on | / |

| | | b1L | use probe for alarm temperature | oFF | _on | _on | / |

| | b2_ | | Probe nr. 2 | | | | |

| | | b2C | calibration offset | -9.0 | 9.0 | 0.0 | K |

| | | b2A | use probe to calculate product average temperature | oFF | _on | _on | / |

| | | b2S | use probe for safety temperature | oFF | _on | _on | / |

| | | b2L | use probe for alarm temperature | oFF | _on | _on | / |

| | b3_ | | Probe nr. 3 | | | | |

| | | b3C | calibration offset | -9.0 | 9.0 | 0.0 | K |

| | | b3A | use probe to calculate product average temperature | oFF | _on | oFF | / |

| | | b3S | use probe for safety temperature | oFF | _on | oFF | / |

| | | b3L | use probe for alarm temperature | oFF | _on | oFF | / |

| | b4_ | | Probe nr. 4 | | | | |

| | | b4C | calibration offset | -9.0 | 9.0 | 0.0 | K |

| | | b4A | use probe to calculate product average temperature | oFF | _on | _on | / |

| | | b4S | use probe for safety temperature | oFF | _on | _on | / |

| | | b4L | use probe for alarm temperature | oFF | _on | _on | / |

| | b5_ | | Probe nr. 5 | | | | |

| | | b5C | calibration offset | -9.0 | 9.0 | 0.0 | % |

| | | b5A | use probe to calculate room humidity | oFF | _on | _on | / |

| | b6_ | | Probe nr. 6 | | | | |

| | | b6C | calibration offset | -9.0 | 9.0 | 0.0 | 10*ppm |

| | | b6A | use probe to calculate room ethylene | oFF | _on | oFF | / |

| | b7_ | | Probe nr. 7 | | | | |

| | | b7C | calibration offset | -9.0 | 9.0 | 0.0 | bar |

| | | b7A | use probe to calculate suction pressure | oFF | _on | _on | / |

| L__ | | | Functions about alarm and stand-by | | | | |

| | Lt_ | | Temperature alarm | | | | |

| 24 | | | LtL | low temperature alarm set point | -55.0 | 145.0 | -2.0 | °C |

| 25 | | | LtH | high temperature alarm set point | -55.0 | 145.0 | 14.0 | °C |

| | | Ltd | alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | Lo_ | | On / stand-by status | | | | |

| 26 | | | Loo | actual status: stand-by or on | oFF | _on | oFF | / |

| d__ | | | Functions about delays | | | | |

| | dF_ | | Delay from previous stop | | | | |

| | | dF6 | delay from request to activation of OUT-6: heating | 0 | 194 4:20:15 | 3:00 | dd hh:mm:ss |

| h__ | | | Functions about keyboard | | | | |

| | hL_ | | Keyboard lock | | | | |

| 27 | | | hLH | keyboard lock / unlock | oFF | _on | oFF | / |

| | | hLP | keyboard lock / unlock password | 0 | 99 | 22 | / |

| | | hLI | extend lock to light operation | oFF | _on | oFF | / |

| | | hLc | extend lock to curtain operation | oFF | _on | _on | / |

| | | hLO | extend lock to door operation | oFF | _on | _on | / |

| I__ | | | Functions about input-output and machine state (read only) | | | | |

| | IA_ | | Analog inputs | | | | |

| | | IA1 | analog input 1 (temperature) | -55.0 | 145.0 | -55.0 | °C |

| | | IA2 | analog input 2 (temperature) | -55.0 | 145.0 | -55.0 | °C |

| | | IA3 | analog input 3 (suction temperature) | -55.0 | 145.0 | -55.0 | °C |

| | | IA4 | analog input 4 (temperature) | -55.0 | 145.0 | -55.0 | °C |

| | | IA5 | analog input 5 (humidity) | 0.0 | 100.0 | 0.0 | % |

| | | IA6 | analog input 6 (ethylene) | 0.0 | 999.0 | 0.0 | 10*ppm |

| | | IA7 | analog input 7 (low pressure) | 0.0 | 999.0 | 0.0 | (gauge) bar |

| | | IA8 | analog input 8 (average temperature) | -55.0 | 145.0 | -55.0 | °C |

| | Id_ | | Digital input | | | | |

| | | Id1 | digital input 1 (ethylene hardware safety) | oFF | _on | oFF | / |

| | | Id2 | digital input 2 (evaporator hardware safety) | oFF | _on | oFF | / |

| | | Id3 | digital input 3 (heating hardware safety) | oFF | _on | oFF | / |

| | | Id4 | digital input 4 (unused) | oFF | _on | oFF | / |

| | | Id5 | digital input 5 (phase-1 software safety ) | oFF | _on | oFF | / |

| | OS_ | | Machine status | | | | |

| | | LLA | actual alarm - read only (0 means no alarm) | 0 | 255 | 0 | / |

| | OA_ | | Analog output | | | | |

| | | OA1 | analog output fan (reserved for aux master inp status) | 0 | 255 | 0 | / |

| | | OA2 | analog output I out (water valve - 4...20 mA - reserved for aux master output status) | 0 | 255 | 0 | / |

| | Od_ | | Digital output | | | | |

| | | Od1 | digital output 1 (refrigeration solenoid) | oFF | _on | oFF | / |

| | | Od2 | digital output 2 (steam producer) | oFF | _on | oFF | / |

| | | Od3 | digital output 3 (air renew) | oFF | _on | oFF | / |

| | | Od4 | digital output 4 (ethylene) | oFF | _on | oFF | / |

| | | Od5 | digital output 5 (evaporator) | oFF | _on | oFF | / |

| | | Od6 | digital output 6 (heating) | oFF | _on | oFF | / |

| | | Od7 | alarm - eventually connected to relay nr. 2 | oFF | _on | oFF | / |

| E__ | | | Functions about slave preferences | | | | |

| | Ed_ | | Functions about network address | | | | |

| | | EdS | slave address for local network communication | 1 | 254 | 1 | / |

| | EY_ | | Functions about display | | | | |

| | | EYY | input to show on display: 8=average temperature / 5=humidity ... | 1 | 8 | 8 | / |

| Nr. |

Remark |

| 1 | During off-time counters continue to count and output is disabled. At reset command they stop and their value is reset. They are restarted by on command. The minus sign on display ("-") means that you already reset timers. |

| 2 | The period of each cycle includes on-time + off-time, that is the overall duration of the cycle. |

| 3 | The "oFF" command disables the ripening functions and enables the storage. The ripening timers continue however to run also if their output is disabled. To restart the ripening timers, please do the "rES" (reset) command. The "on_" command enables the ripening functions without restarting the timers. To begin a new ripening cycle, please do the "rES" command. The minus sign on display ("-") means that you have already reset the timers. |

| 4 | At the end of the ripening cycle the temperature is set to t5 until the manual reset of the ripening cycle. |

| 5 | The stop command resets forced operation counter. |

| 6 | In case of probe control, ethylene timers and settings are not used. You can still activate forced injections. In case of disabled probe, rYY is used to control curtain string motor when curtain is idle. |

| 7 | To synchronize ethylene injection and ripening start, set dY0 = _d0. |

| 8 | First ethylene injection is delayed until room temperature reaches _tY. _tY has no effect over following ethylene injections. |

| 9 | To synchronize the beginning of further ethylene injections and air renews, set dY3=dA3. |

| 10 | To synchronize the cycles of further ethylene injections and air renews, set dY3=dA3. |

| 11 | Set by the microcontroller - can be manually overwritten. |

| 12 | Door operation disables every other keyboard operation. |

| 13 | The first pressure of push button inside the room - near the door - switches on the light, the second one opens the door, the third one activates the "man in room" alarm. |

| 14 | During the delay the flashing light is on. |

| 15 | For your safety, do not modify this parameter. This setting is supposed to be used just in case of emergency or testing. |

| 16 | No action if the light is switched on from inside the room. |

| 17 | Curtain operation disables every other operation keyboard operation. |

| 18 | For safety reason, door operation is disabled when curtain is enabled. Unrolling can be started also by a push button located near the depressure box, inside the room. |

| 19 | When off, the refrigeration solenoid is steadily on during cooling, as long as overheating is higher then vtL or b3A is off. |

| 20 | Caution! Low overheating causes liquid return and compressor damage. |

| 21 | Caution! Short duty cycle reduces valve life. |

| 22 | Caution! Low overheating causes liquid return and compressor damage. |

| 23 | Caution! High adaptation speed causes swing in the suction line and damage to the compressor. |

| 24 | The low temperature differential is fixed, and alarm status stops at 0.2 °C above the set point. |

| 25 | The high temperature differential is fixed, and alarm status stops at 0.2 °C under the set point. |

| 26 | Passing from stand-by to on and at power on, there is a 5 second delay spent in a virtual stand-by. |

| 27 | When keyboard is locked it is possible to read parameters but is not possible to modify them. To exit the lock it is necessary to write the password. |

| How to ... |

Function |

| Switch between on and stand-by. | Keep pressed B3 button, to activate and deactivate stand-by. In stand-by every output is disabled except light, leds from L1 to L6 blink, timers continue to count. |

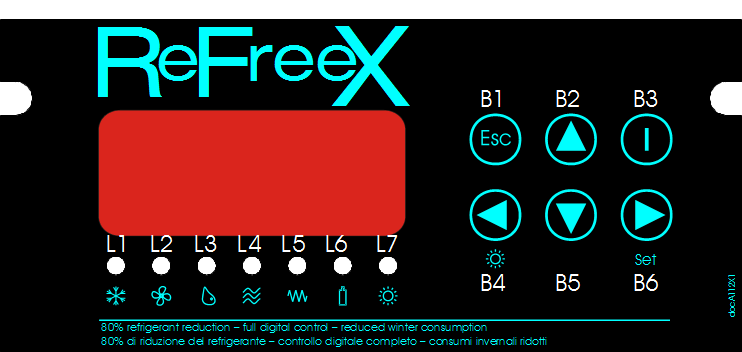

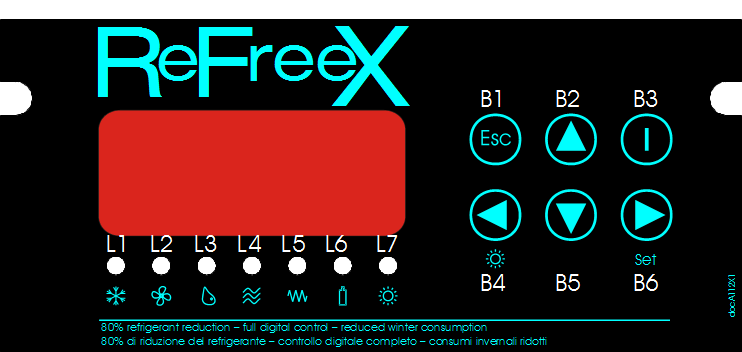

| Program the menu. | Keep pressed B6 to enter the menu. Navigate up and down with B2 and B5. Select the submenu by B6. Change the parameter by B2 and B5, press B6 to confirm, or B4 to go back without saving. The changes will have effect after the exit from programming pressing B4 repeatedly. Press B1 to exit immediately without saving any parameter. |

| Show or change temperature set. | Press shortly B6 - the display shows the current set point - change it by B2 and B5, and confirm it by B6. As alternative, enter the menu program as explained above, modify the parameter _t0, then confirm it. |

| Reset timers. | For the resettable controls in the menu program, confirming "rES", then confirming "on_" or "oFF", has the joint effect of resetting timers and going into the enabled or disabled status. |

| Enter ripening mode. | Keep pressed B6+B3. As alternative, enter the menu program as explained above, set the parameter rrH, reset it in case it is a new ripening, then confirm it. |

| Enter storage mode. | Keep pressed B6+B1. As alternative, enter the menu program as explained above, set to oFF the parameter rrH, then confirm it. |

| Door operation. | Push B2 to open, B5 to close, and B1 to stop. If you are inside the room and the door is closed, press B7 once to switch on the light, press again to open the door, and again to trigger the man in room alarm. During door operation display shows "OPE" or "CLO". By default, when the door is open, the light is on and every other output is off. By default, door operation is disabled after the first ethylene injection and before subsequent air renew. |

| Curtain operation. | For safety reason, the curtain can be operated only when the door is fully open and the light is on. To activate the keyboard for the curtain, keep pressed B6+B4, then press shortly B6 or B8 to unroll, B4 to roll, B1 to stop, and again B1 to exit curtain mode. During curtain operation, every output is disabled. The display shows "Cur" with the curtain idle, "Unr" during unrolling, and "rOL" during rolling. |