| Rem. |

Parameter |

Description |

Minimum |

Maximum |

Default |

Unit |

| S__ | | | Functions about storage | | | | |

| | St_ | | Functions about storage temperature | | | | |

| | | _t0 | storage room temperature | -55.0 | 145.0 | 2.0 | °C |

| | | _tb | dead band | 0.0 | 50.0 | 0.0 | K |

| | | _td | differential | 0.0 | 50.0 | 0.2 | K |

| | | _tH | maximum set point of temperature from slave keyboard | -55.0 | 145.0 | 45.0 | °C |

| | | _tL | minimum set point of temperature from slave keyboard | -55.0 | 145.0 | -55.0 | °C |

| | | _i0 | storage room humidity | 0.0 | 100.0 | 85.0 | % |

| | | _ib | dead band | 0.0 | 50.0 | 0.0 | % |

| | | _id | differential | 0.0 | 50.0 | 5.0 | % |

| | | _iH | maximum set point of humidity from slave keyboard | 0.0 | 100.0 | 100.0 | % |

| | | _iL | minimum set point of humidity from slave keyboard | 0.0 | 100.0 | 0.0 | % |

| | SA_ | | Functions about air renew during storage | | | | |

| | | SAH | enable air renew during storage | oFF | _on | oFF | / |

| | | SA0 | immediate delay before first air renew | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| | | SAd | on-time duration in the air renew cycle | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | SAP | period of air renew cycle | 0 | 194 4:20:15 | 12:00:00 | dd hh:mm:ss |

| | | SAh | enable forced air renew by keyboard short cut | oFF | _on | _on | / |

| | | SAF | forced air renew duration | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | SAo | start / stop forced air renew | oFF | _on | oFF | / |

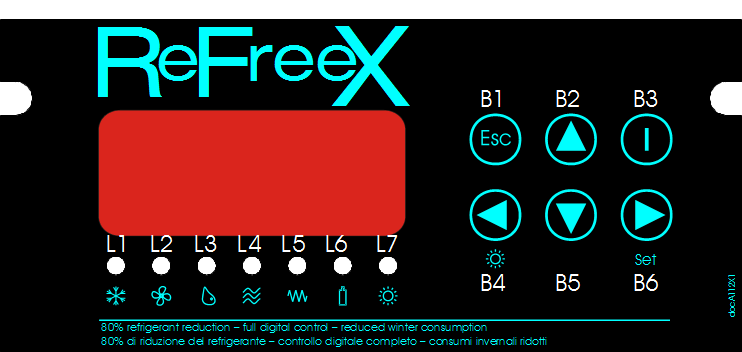

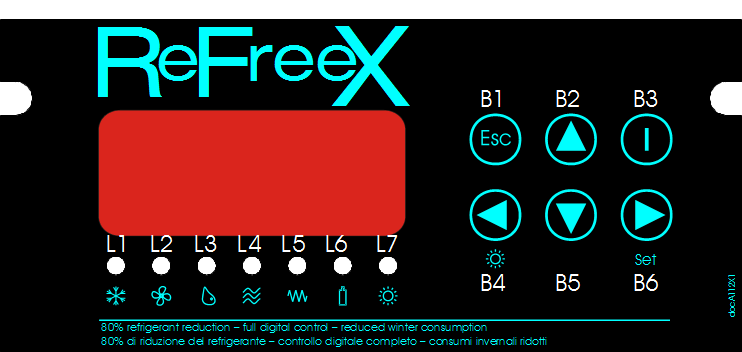

| | Fd_ | | Functions about defrost duration and timing | | | | |

| 1 | | | Fd0 | immediate delay before next defrost | 0 | 194 4:20:15 | 0 | dd hh:mm:ss |

| | | Fdd | on-time duration of the defrost | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | Fdg | dripping time after defrost | 0 | 194 4:20:15 | 2:00 | dd hh:mm:ss |

| | | FdE | evaporator fan activation delay after the defrost | 0 | 194 4:20:15 | 15:00 | dd hh:mm:ss |

| 2 | | | FdP | overall period of the defrost | 0 | 194 4:20:15 | 4:00:00 | dd hh:mm:ss |

| | | Fd1 | evaporator fan pulse duration (0.001 s units - select 0 for no pulse during defrost) | 0 | 255 | 0 | / |

| | | Fd2 | evaporator fan pulse period | 0 | 194 4:20:15 | 1:00 | dd hh:mm:ss |

| | FF_ | | Functions about forced defrost | | | | |

| | | FFh | enable forced defrost by keyboard short cut | oFF | _on | _on | / |

| | | FFd | forced defrost duration | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| 3 | | | FFo | start immediate forced defrost | oFF | _on | oFF | / |

| | FP_ | | Functions about defrost preference | | | | |

| 4 | | | FPt | defrost type: 0=none / 1=pause / 2=air / 3=electric / 4=hot gas / 5=heat pump / 6=heat pump by hp | 0 | 255 | 2 | / |

| | Ft_ | | Functions about defrost temperature | | | | |

| 5 | | | Ftt | defrost stop temperature | -55.0 | 146.0 | 6.0 | °C |

| M__ | | | Functions about compressor | | | | |

| | MU_ | | Functions about pressure switches | | | | |

| 6 | | | MLH | low pressure safety restart ( similar to Danfoss KP15 lp set point ) | 0.0 | 99.0 | 1.2 | (gauge) bar |

| | | MLL | low pressure safety stop ( similar to Danfoss KP15 lp set point - differential ) | 0.0 | 99.0 | 0.2 | (gauge) bar |

| | | MHH | high pressure safety stop ( similar to Danfoss KP15 hp set point ) | 0.0 | 99.0 | 28.0 | (gauge) bar |

| | | MHL | high pressure safety restart ( similar to Danfoss KP15 hp set point - differential ) | 0.0 | 99.0 | 24.0 | (gauge) bar |

| 7 | | | MUO | minimum oil differential pressure | 0.0 | 30.0 | 2.0 | (gauge) bar |

| 8 | | | MUU | enable pump down | oFF | _on | oFF | / |

| H__ | | | Heating | | | | |

| | HP_ | | Heating preference | | | | |

| | | HPP | heating method: 0=none / 1=electric / 2=hot gas / 3=heat pump / 4=intern heat pump / 5=ihp+d / 6=hp+d / 7=hg+d | 0 | 255 | 0 | / |

| | | HPF | heating source: 0=dedicated heating / 1=defrost / 2=light | 0 | 2 | 0 | / |

| U__ | | | Dehumidification | | | | |

| | UP_ | | Dehumidification preference | | | | |

| | | UPP | alternate refrigeration and heating | oFF | _on | oFF | / |

| 9 | | | UP1 | during concurrent run force active heating | oFF | _on | oFF | / |

| n__ | | | Functions about fans | | | | |

| | nc_ | | Functions about condenser fans | | | | |

| | | ncH | enable condenser fans when compressor is off and discharge pressure is over maximum | oFF | _on | _on | / |

| 10 | | | ncr | enable condenser fans speed regulation | oFF | _on | _on | / |

| 11 | | | ncU | fan minimum speed | 0 | 255 | 40 | / |

| | | ncd | minimum HP-LP-difference to keep on fans | 0.0 | 99.0 | 2.0 | (gauge) bar |

| | | n1H | fan 1 start pressure ( similar to Danfoss KP5 set point ) - active just when ncr is oFF | 0.0 | 99.0 | 10.0 | (gauge) bar |

| 12 | | | n1L | fan 1 stop pressure ( similar to Danfoss KP5 set point - differential ) | 0.0 | 99.0 | 6.0 | (gauge) bar |

| | nE_ | | Functions about evaporator fans | | | | |

| | | nEH | force evaporator fans when refrigeration is off | oFF | _on | oFF | / |

| c__ | | | Functions about door and light | | | | |

| | cP_ | | Door switch and evaporator fan | | | | |

| | | cPH | stop evaporator fans when door is open | oFF | _on | _on | / |

| | | cPF | pause defrost timer when air defrost is suspended by evaporator fan stop | oFF | _on | _on | / |

| | | cPd | delay of fan automatic switch on | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | cI_ | | Functions about light | | | | |

| | | cIH | switch on the light when the door is open and off when closed | oFF | _on | _on | / |

| 13 | | | cIo | switch off the light automatically if it has been switched on from outside | oFF | _on | _on | / |

| | | cId | delay of light automatic switch off | 0 | 194 4:20:15 | 30 | dd hh:mm:ss |

| v__ | | | Functions about electronic expansion valve | | | | |

| | vP_ | | Functions about electronic expansion valve preference | | | | |

| 14 | | | vPH | enable electronic expansion valve | oFF | _on | _on | / |

| | | vPP | refrigerant gas type: 0=R134A / 1=R404A / 2=R507A / 3=R22 / 4=R407C / 5=R407F / 6=R407A / 7=R410A / 8=R290 / 9=R1270 / 10=R744 / 11=R717 / 12=R1234y / 13=R1234z / 14=R449A / 15=R448A / 16=R452A / 17=R450A / 18=R513A / 19=R407H / 20=R23 / 21=R455A | 0 | 255 | 0 | / |

| | vt_ | | Functions about electronic expansion valve temperature | | | | |

| 15 | | | vtt | wanted overheating (similar to Danfoss thermostatic overheating spring regulation) | 0.0 | 99.0 | 8.0 | K |

| 16 | | | vtH | maximum overheating | 0.0 | 99.0 | 99.0 | K |

| 17 | | | vtL | minimum overheating | 0.0 | 99.0 | 6.0 | K |

| | | vtU | maximum pressure allowed in the suction line (similar to Danfoss MOP) | 0.0 | 30.0 | 10.0 | (gauge) bar |

| | vd_ | | Functions about electronic expansion valve timing | | | | |

| 18 | | | vd1 | on-off duty cycle duration | 0 | 194 4:20:15 | 8 | dd hh:mm:ss |

| 19 | | | vd2 | on duty cycle duration at refrigeration start (set to 0 for previous stop value) | 0 | 194 4:20:15 | 5 | dd hh:mm:ss |

| 20 | | | vdd | on duty cycle adaptation speed (low value for slow adaptation and small swinging) | 0 | 255 | 8 | / |

| b__ | | | Functions about probe calibration | | | | |

| | b1_ | | Probe nr. 1 | | | | |

| | | b1C | room temperature | -99.0 | 99.0 | 0.0 | K |

| | | b1A | enable probe | oFF | _on | _on | / |

| | b2_ | | Probe nr. 2 | | | | |

| | | b2C | defrost temperature | -99.0 | 99.0 | 0.0 | K |

| | | b2A | enable probe | oFF | _on | _on | / |

| | b3_ | | Probe nr. 3 | | | | |

| | | b3C | suction temperature | -99.0 | 99.0 | 0.0 | K |

| | | b3A | enable probe | oFF | _on | _on | / |

| | b4_ | | Probe nr. 4 | | | | |

| 21 | | | b4C | engine room temperature | -99.0 | 99.0 | 0.0 | K |

| | | b4A | enable probe | oFF | _on | _on | / |

| | b5_ | | Probe nr. 5 | | | | |

| | | b5C | humidity | -99.0 | 99.0 | 0.0 | % |

| | | b5A | enable probe | oFF | _on | oFF | / |

| | b6_ | | Probe nr. 6 | | | | |

| | | b6C | high pressure (HP) | -99.0 | 99.0 | 0.0 | bar |

| | | b6A | enable probe | oFF | _on | _on | / |

| | b7_ | | Probe nr. 7 | | | | |

| | | b7C | low pressure (LP) | -99.0 | 99.0 | 0.0 | bar |

| | | b7A | enable probe | oFF | _on | _on | / |

| | b8_ | | Probe nr. 8 | | | | |

| | | b8C | discharge temperature | -99.0 | 99.0 | 0.0 | K |

| | | b8A | enable probe | oFF | _on | _on | / |

| | b9_ | | Probe nr. 9 | | | | |

| | | b9C | oil pressure - eventually connected to AN-5 | -99.0 | 99.0 | 0.0 | bar |

| | | b9A | enable probe | oFF | _on | oFF | / |

| L__ | | | Functions about alarm and stand-by | | | | |

| | Lt_ | | Temperature alarm | | | | |

| 22 | | | LtL | low temperature alarm set point | -55.0 | 145.0 | -2.0 | °C |

| 23 | | | LtH | high temperature alarm set point | -55.0 | 145.0 | 14.0 | °C |

| | | Ltd | alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | LF_ | | Full stop temperature alarm | | | | |

| | | LFL | low temperature alarm set point | -55.0 | 145.0 | -5.0 | °C |

| | | LFH | high temperature alarm set point | -55.0 | 145.0 | 20.0 | °C |

| | | LFd | alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | Li_ | | Humidity alarm | | | | |

| | | LiL | low humidity alarm set point | 0.0 | 100.0 | 0.0 | % |

| | | LiH | high humidity alarm set point | 0.0 | 100.0 | 100.0 | % |

| | | Lid | alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | Lj_ | | Full stop humidity alarm | | | | |

| | | LjL | low humidity alarm set point | 0.0 | 100.0 | 0.0 | % |

| | | LjH | high humidity alarm set point | 0.0 | 100.0 | 100.0 | % |

| | | Ljd | alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | LO_ | | Door alarm | | | | |

| | | LOH | enable door alarm | oFF | _on | _on | / |

| | | LOd | door alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | LOt | temperature alarm minimum delay after door opening | 0 | 194 4:20:15 | 15:00 | dd hh:mm:ss |

| | LI_ | | Other alarm inputs | | | | |

| | | L1H | enable digital input 1 alarm (compressor safety devices) | oFF | _on | _on | / |

| | | L1d | digital input 1 alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | L2H | enable digital input 2 alarm (evaporator safety) | oFF | _on | _on | / |

| | | L2d | digital input 2 alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | L3H | enable digital input 3 alarm (heating safety thermostat) | oFF | _on | _on | / |

| | | L3d | digital input 3 alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | L5H | enable digital input 5 alarm (compressor phase monitor / thermal overload relay) | oFF | _on | _on | / |

| | | L5d | digital input 5 alarm delay | 0 | 194 4:20:15 | 1 | dd hh:mm:ss |

| | Lo_ | | On / stand-by status | | | | |

| 24 | | | Loo | actual status: stand-by or on | oFF | _on | oFF | / |

| d__ | | | Functions about delays | | | | |

| | dF_ | | Delay from previous stop | | | | |

| | | dF4 | delay from stop to activation of relay nr. 4 - compressor | 0 | 194 4:20:15 | 5:00 | dd hh:mm:ss |

| P__ | | | Functions about master preferences | | | | |

| | Pd_ | | Functions about network address | | | | |

| | | PdM | master address for global network communication | 0 | 254 | 1 | / |

| | | PdS | number of slaves connected to this master | 1 | 2 | 2 | / |

| | PO_ | | Output assignment | | | | |

| | | PO2 | assign out-2 relay to: 0=alarm / 1=heating / 2=steam / 3=air renew / 4=defrost duty / 5=steam on FAN / 6=outer dehum / 7=OUT1 / 8=OUT3 / 9=OUT4 / 10=OUT5 / 11=OUT6 / 12=FAN / 13=alarm NO / 14=fan off dehum / 15=drain pump / 16=ss FAN / 17=16+2rm / 18=17+drp / 19=18+sdrp OUT6 / 20=5+14 / 21=alt heat ev / 22=19+ss OUT3 / 23=depr OUT2 / 24=Loo / 25=off / 26=ss OUT3 / 27=mc part / 28=eco OUT3 / 29=28+ip / 30=27+28 / 31=27+29 / 32=29+es AN2 / 33=27+32 / 34=ev FAN / 35=34+2 / 36=ss / 37=34+2mcs / 38=37+steam OUT3 | 0 | 255 | 0 | / |

| I__ | | | Functions about input-output and machine state (read only) | | | | |

| | IA_ | | Analog inputs | | | | |

| | | IA1 | room temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA2 | defrost temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA3 | suction temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA4 | engine room temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA5 | humidity | 0.0 | 100.0 | 0.0 | % |

| | | IA6 | high pressure (HP) | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | | IA7 | low pressure (LP) | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | | IA8 | discharge temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA9 | oil pressure - eventually connected to AN-5 | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | Id_ | | Digital input | | | | |

| | | Id1 | compressor hardware safety | oFF | _on | oFF | / |

| | | Id2 | evaporator hardware safety | oFF | _on | oFF | / |

| | | Id3 | defrost hardware safety | oFF | _on | oFF | / |

| | | Id4 | door closed | oFF | _on | oFF | / |

| | | Id5 | phase software safety | oFF | _on | oFF | / |

| | OS_ | | Machine status | | | | |

| | | OSn | evaporator fan stopped by door opening or manual control | oFF | _on | oFF | / |

| | OA_ | | Analog output | | | | |

| | | LLA | actual alarm - read only (0 means no alarm) | 0 | 255 | 0 | / |

| | | OA1 | condenser | 0 | 255 | 0 | / |

| | | OA2 | humidity - 4...20 mA | 0 | 255 | 0 | / |

| | Od_ | | Digital output | | | | |

| 25 | | | Od1 | solenoid | oFF | _on | oFF | / |

| | | Od2 | heating | oFF | _on | oFF | / |

| | | Od3 | light | oFF | _on | oFF | / |

| | | Od4 | compressor | oFF | _on | oFF | / |

| | | Od5 | evaporator | oFF | _on | oFF | / |

| | | Od6 | defrost | oFF | _on | oFF | / |

| | | Od7 | alarm - eventually connected to OUT-2 | oFF | _on | oFF | / |

| | | Od8 | steam producer - eventually connected OUT-2 | oFF | _on | oFF | / |

| | | Od9 | air renew - eventually connected to OUT-2 | oFF | _on | oFF | / |

| E__ | | | Functions about slave preferences | | | | |

| | Ed_ | | Functions about network address | | | | |

| | | EdS | slave address for local network communication | 1 | 254 | 1 | / |

| | EY_ | | Functions about display | | | | |

| | | EYY | input to show on display: 1=IA1 / 2=IA2 ... | 0 | 255 | 1 | / |

| | | EYr | enable display rotation: 0=off / 1=all / 2=selected | 0 | 2 | 0 | / |

| | E0_ | | Functions about display rotation, when EYr=1 | | | | |

| | | E0d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E0E | duration of value display during rotation | 0 | 255 | 2 | / |

| | E1_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E1d | duration of label display during rotation | 0 | 255 | 0 | / |

| | | E1t | label text during rotation | 000 | yyy | rM= | / |

| | | E1E | duration of value display during rotation | 0 | 255 | 6 | / |

| | E2_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E2d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E2t | label text during rotation | 000 | yyy | dE= | / |

| | | E2E | duration of value display during rotation | 0 | 255 | 0 | / |

| | E3_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E3d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E3t | label text during rotation | 000 | yyy | SU= | / |

| | | E3E | duration of value display during rotation | 0 | 255 | 0 | / |

| | E4_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E4d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E4t | label text during rotation | 000 | yyy | Er= | / |

| | | E4E | duration of value display during rotation | 0 | 255 | 0 | / |

| | E5_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E5d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E5t | label text during rotation | 000 | yyy | rH= | / |

| | | E5E | duration of value display during rotation | 0 | 255 | 4 | / |

| | E6_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E6d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E6t | label text during rotation | 000 | yyy | HP= | / |

| | | E6E | duration of value display during rotation | 0 | 255 | 0 | / |

| | E7_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E7d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E7t | label text during rotation | 000 | yyy | LP= | / |

| | | E7E | duration of value display during rotation | 0 | 255 | 0 | / |

| | E8_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E8d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E8t | label text during rotation | 000 | yyy | dI= | / |

| | | E8E | duration of value display during rotation | 0 | 255 | 0 | / |

| | E9_ | | Functions about display rotation, when EYr=2 (repeated for each parameter) | | | | |

| | | E9d | duration of label display during rotation | 0 | 255 | 1 | / |

| | | E9t | label text during rotation | 000 | yyy | oI= | / |

| | | E9E | duration of value display during rotation | 0 | 255 | 0 | / |

| | Eb_ | | Functions about buzzer | | | | |

| | | EbH | enable buzzer | 0 | 1 | 1 | / |

| | EF_ | | Functions about slave default | | | | |

| 26 | | | EFF | reload slave default parameters from EEPROM, at next restart | 0 | 1 | 0 | / |

| | EP_ | | Functions about slave password | | | | |

| 27 | | | EPA | set a new password | 000 | yyy | ___ | / |

| Nr. |

Remark |

| 1 | Defrost is not performed twice in case safety switches of mc or evaporator are not ok. |

| 2 | The period of each cycle includes on-time + off-time, that is the overall duration of the cycle. |

| 3 | Following defrost cycles will be aligned to the end of forced one. |

| 4 | Add 100 to FPt parameter to enable the outer defrost drive on INP-4. The defrost is initiated by INP-4 closure; after defrost and until INP-4 is closed, the instrument does not leave the dripping mode, to coordinate with eventual other instruments. |

| 5 | In case of hot gas defrost, both IA2 and IA3 must reach Ftt. |

| 6 | When MLH<MLL,there is a delay of 10*(MLL-MLH) seconds on lp switch. Eventual pumpdown restart is over MLH+1 bar. |

| 7 | Fixed time 120 s and manual reset. |

| 8 | When activated, a clever pump down algorithm coordinates the solenoid, the evaporator and the mc. There is a 15 minutes delay between mc restarts. When MLL=MLH there is no restart at all. There is no concurrent run of mc and electric defrost or heating. |

| 9 | Forced refrigeration is disabled when room temperature is under LFL, forced heating is disabled over LFH. |

| 10 | When speed regulation is off the fan is operated on-off. |

| 11 | Caution! Speed regulation can cause fan fault or electronic board fault. Low and average minimum speed can increase the risk. |

| 12 | During the first 10 seconds of speed regulation, the n1L is replaced by (n1H+n1L)/2. |

| 13 | No action if the light is switched on from inside the room. |

| 14 | When off, the refrigeration solenoid is steadily on during cooling, as long as overheating is higher then vtL or b3A is off. |

| 15 | Caution! Low overheating causes liquid return and compressor damage. |

| 16 | Overheating over the maximum forces valve anticipated opening. |

| 17 | Overheating under the minimum delays valve opening. |

| 18 | Caution! Short duty cycle reduces valve life. |

| 19 | Caution! Low overheating causes liquid return and compressor damage. |

| 20 | Caution! High adaptation speed causes swing in the suction line and damage to the compressor. |

| 21 | In H422V9, starting from revision 14, when b1A is on, b4A is off, and b4C is non-zero, use AN-4 reading with set at 0.0 °C + b4C to concur for low temperature alarm and to stop cooling. |

| 22 | The low temperature differential is fixed, and alarm status stops at 0.2 °C above the set point. |

| 23 | The high temperature differential is fixed, and alarm status stops at 0.2 °C under the set point. |

| 24 | Passing from stand-by to on and at power on, there is a 5 second delay spent in a virtual stand-by. |

| 25 | The minus sign on display ("-") signals that output is going to start after a delay. |

| 26 | This parameter is a late addition, not present on every instrument |

| 27 | The use of this parameter is restricted to ReFreeX authorized personnel; further detail is available on demand. This parameter is not implemented on every instrument. The value and the action of this parameter are local to each slave. If you are unsure, during action relative to this parameter, press B1 at any moment. Three underscores, three zero digits, and three empty-characters are considered trivial password values; any other combination of three alphanumeric characters is a non-trivial password. If a non-trivial password value is set, then entering the menu, the label PAS is shown. Press B6, then introduce the password, confirm by B6, and press B4. If the introduced value does not match the saved password, then the label PAS is shown again, and the operation may be retried for a maximum of other two times. In case of unlocking failure, the label bAd is shown. To exit, press B4 twice or B1 once. To remove the password, set EPA to value 000 . To set or to change the password, if you know the authorization code, set EPA to a new non-trivial value, and exit the menu. The label rEP is shown. Press B6, then reintroduce the same password, confirm by B6, and press B4. The label AUt is shown. Press B6, then introduce the authorization code, confirm by B6, and press B4. |