| Rem. |

Parameter |

Description |

Minimum |

Maximum |

Default |

Unit |

| M__ | | | Functions about compressor | | | | |

| | MU_ | | Functions about pressure switches | | | | |

| | | ML0 | suction low pressure regulation (similar to Danfoss RT1AL set point minus half of neutral zone) | 0.0 | 99.0 | 2.8 | (gauge) bar |

| | | MLb | suction pressure regulation dead band (ML0 +/- MLb are the upper/lower limits) | 0.0 | 99.0 | 0.5 | bar |

| | | MLd | suction pressure regulation differential (loading at ML0+MLb+MLd / unl at ML0-MLb-MLd) | 0.0 | 99.0 | 0.2 | bar |

| | | MH0 | discharge (HP) pressure limit forcing the timed compressor unload | 0.0 | 99.0 | 24.0 | (gauge) bar |

| 1 | | | MLH | low pressure safety restart ( similar to Danfoss KP15 lp set point ) | 0.0 | 99.0 | 1.2 | (gauge) bar |

| | | MLL | low pressure safety stop ( similar to Danfoss KP15 lp set point - differential ) | 0.0 | 99.0 | 0.2 | (gauge) bar |

| | | MHH | high pressure safety stop ( similar to Danfoss KP15 hp set point ) | 0.0 | 99.0 | 28.0 | (gauge) bar |

| | | MHL | high pressure safety restart ( similar to Danfoss KP15 hp set point - differential ) | 0.0 | 99.0 | 24.0 | (gauge) bar |

| 2 | | | MU1 | minimum oil differential pressure of compressor nr. 1 | 0.0 | 99.0 | 1.0 | bar |

| | | MU2 | minimum oil differential pressure of compressor nr. 2 | 0.0 | 99.0 | 1.0 | bar |

| 3 | | | MU3 | minimum oil differential pressure of compressor nr. 3 | 0.0 | 99.0 | 1.0 | bar |

| | | Mut | minimum oil receiver temperature before opening the oil solenoid | -55.0 | 145.0 | 25.0 | °C |

| 4 | | | MM1 | usage of mc nr. 1 output: 0=off / 1=on / 2=auto / 3=slave no / 4=slave nc / 5=kriwan | 0 | 5 | 2 | / |

| | | MM2 | usage of mc nr. 2 output: 0=off / 1=on / 2=auto / 3=slave no / 4=slave nc / 5=kriwan | 0 | 5 | 2 | / |

| | | MM3 | usage of mc nr. 3 output: 0=off / 1=on / 2=auto / 3=slave no / 4=slave nc / 5=kriwan | 0 | 5 | 2 | / |

| 5 | | | MMH | enable external load override on INP-4 | oFF | _on | oFF | / |

| 6 | | | MMd | external load override delay | 0 | 194 4:20:15 | 1:00:00 | dd hh:mm:ss |

| n__ | | | Functions about fans | | | | |

| | nc_ | | Functions about condenser fans | | | | |

| | | ncH | enable condenser fans when compressor is off and discharge pressure is over maximum | oFF | _on | _on | / |

| 7 | | | ncr | enable condenser fans speed regulation | oFF | _on | _on | / |

| 8 | | | ncU | fan minimum speed | 0 | 255 | 40 | / |

| | | ncd | minimum HP-LP-difference to keep on fans | 0.0 | 99.0 | 2.0 | (gauge) bar |

| | | n1H | fan 1 start pressure ( similar to Danfoss KP5 set point ) - active just when ncr is oFF | 0.0 | 99.0 | 10.0 | (gauge) bar |

| 9 | | | n1L | fan 1 stop pressure ( similar to Danfoss KP5 set point - differential ) | 0.0 | 99.0 | 6.0 | (gauge) bar |

| | | n2H | fan 2 start pressure | 0.0 | 99.0 | 7.0 | (gauge) bar |

| | | n2L | fan 2 stop pressure | 0.0 | 99.0 | 5.0 | (gauge) bar |

| | | n3H | fan 3 start pressure | 0.0 | 99.0 | 8.0 | (gauge) bar |

| | | n3L | fan 3 stop pressure | 0.0 | 99.0 | 6.0 | (gauge) bar |

| | | n4H | fan 4 start pressure | 0.0 | 99.0 | 9.0 | (gauge) bar |

| | | n4L | fan 4 stop pressure | 0.0 | 99.0 | 7.0 | (gauge) bar |

| b__ | | | Functions about probe calibration | | | | |

| | b1_ | | Probe nr. 1 | | | | |

| | | b1C | oil receiver temperature | -99.0 | 99.0 | 0.0 | K |

| | | b1A | enable probe | oFF | _on | _on | / |

| | b2_ | | Probe nr. 2 | | | | |

| | | b2C | discharge temperature | -99.0 | 99.0 | 0.0 | K |

| | | b2A | enable probe | oFF | _on | _on | / |

| | b3_ | | Probe nr. 3 | | | | |

| | | b3C | engine room temperature | -99.0 | 99.0 | 0.0 | K |

| | | b3A | enable probe | oFF | _on | _on | / |

| | b4_ | | Probe nr. 4 | | | | |

| | | b4C | mc1 oil pressure | -99.0 | 99.0 | 0.0 | bar |

| | | b4A | enable probe | oFF | _on | _on | / |

| | b5_ | | Probe nr. 5 | | | | |

| | | b5C | mc2 oil pressure | -99.0 | 99.0 | 0.0 | bar |

| | | b5A | enable probe | oFF | _on | _on | / |

| | b6_ | | Probe nr. 6 | | | | |

| | | b6C | mc3 oil pressure | -99.0 | 99.0 | 0.0 | bar |

| | | b6A | enable probe | oFF | _on | _on | / |

| | b7_ | | Probe nr. 7 | | | | |

| | | b7C | high pressure (HP) | -99.0 | 99.0 | 0.0 | bar |

| | | b7A | enable probe | oFF | _on | _on | / |

| | b8_ | | Probe nr. 8 | | | | |

| | | b8C | low pressure (LP) | -99.0 | 99.0 | 0.0 | bar |

| | | b8A | enable probe | oFF | _on | _on | / |

| L__ | | | Functions about alarm and stand-by | | | | |

| | LI_ | | Other alarm inputs | | | | |

| | | L1H | enable mc1 alarm | oFF | _on | _on | / |

| | | L1d | mc1 alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | L2H | enable mc2 alarm | oFF | _on | _on | / |

| | | L2d | mc2 alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | L3H | enable mc3 alarm | oFF | _on | _on | / |

| | | L3d | mc3 alarm delay | 0 | 194 4:20:15 | 30:00 | dd hh:mm:ss |

| | | L4H | enable external override alarm | oFF | _on | _on | / |

| | | L4d | override alarm delay | 0 | 194 4:20:15 | 1:00:00 | dd hh:mm:ss |

| | | L5H | enable digital input 5 alarm (compressor phase monitor / thermal overload relay) | oFF | _on | _on | / |

| | | L5d | digital input 5 alarm delay | 0 | 194 4:20:15 | 1 | dd hh:mm:ss |

| | Lo_ | | On / stand-by status | | | | |

| 10 | | | Loo | actual status: stand-by or on | oFF | _on | oFF | / |

| d__ | | | Functions about delays | | | | |

| | dF_ | | Delay from previous stop | | | | |

| | | dF4 | mc1 start delay | 0 | 194 4:20:15 | 5:00 | dd hh:mm:ss |

| | | dF5 | mc2 start delay | 0 | 194 4:20:15 | 10:00 | dd hh:mm:ss |

| | | dF6 | mc3 start delay | 0 | 194 4:20:15 | 15:00 | dd hh:mm:ss |

| | | dS4 | mc1 stop delay | 0 | 194 4:20:15 | 45 | dd hh:mm:ss |

| | | dS5 | mc2 stop delay | 0 | 194 4:20:15 | 30 | dd hh:mm:ss |

| | | dS6 | mc3 stop delay | 0 | 194 4:20:15 | 15 | dd hh:mm:ss |

| P__ | | | Functions about master preferences | | | | |

| | Pd_ | | Functions about network address | | | | |

| | | PdM | master address for global network communication | 0 | 254 | 1 | / |

| | | PdS | number of slaves connected to this master | 1 | 2 | 2 | / |

| | Pb_ | | Suction pressure broadcast | | | | |

| | | PbH | enable suction pressure periodic broadcast over the PC net | oFF | _on | _on | / |

| | | Pbd | delay between pressure broadcast messages | 0 | 194 4:20:15 | 30 | dd hh:mm:ss |

| | | Pbb | delay between latest received message and broadcasting start | 0 | 194 4:20:15 | 2:00 | dd hh:mm:ss |

| I__ | | | Functions about input-output and machine state (read only) | | | | |

| | IA_ | | Analog inputs | | | | |

| | | IA1 | oil receiver temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA2 | discharge temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA3 | engine room temperature | -55.0 | 145.0 | -55.0 | °C |

| | | IA4 | oil pressure of mc1 | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | | IA5 | oil pressure of mc2 | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | | IA6 | oil pressure of mc3 | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | | IA7 | high pressure (HP) | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | | IA8 | low pressure (LP) | 0.0 | 30.0 | 0.0 | (gauge) bar |

| | Id_ | | Digital input | | | | |

| | | Id1 | mc1 hardware safety | oFF | _on | oFF | / |

| | | Id2 | mc2 hardware safety | oFF | _on | oFF | / |

| | | Id3 | mc3 hardware safety | oFF | _on | oFF | / |

| | | Id4 | external override | oFF | _on | oFF | / |

| | | Id5 | phase software safety | oFF | _on | oFF | / |

| | OA_ | | Analog output | | | | |

| | | LLA | actual alarm - read only (0 means no alarm) | 0 | 255 | 0 | / |

| | | OA1 | condenser | 0 | 255 | 0 | / |

| | | OA2 | humidity - 4...20 mA | 0 | 255 | 0 | / |

| | Od_ | | Digital output | | | | |

| 11 | | | Od1 | condenser fan 2 | oFF | _on | oFF | / |

| | | Od2 | condenser fan 3 | oFF | _on | oFF | / |

| | | Od3 | condenser fan 4 | oFF | _on | oFF | / |

| | | Od4 | compressor 1 | oFF | _on | oFF | / |

| | | Od5 | compressor 2 | oFF | _on | oFF | / |

| | | Od6 | compressor 3 | oFF | _on | oFF | / |

| | | Od7 | oil receiver solenoid - eventually connected to OUT-3 | oFF | _on | oFF | / |

| | | Od8 | alarm - eventually connected to OUT-3 | oFF | _on | oFF | / |

| E__ | | | Functions about slave preferences | | | | |

| | EY_ | | Functions about display | | | | |

| | | EYY | input to show on display: 1=IA1 / 2=IA2 ... | 0 | 255 | 1 | / |

| Nr. |

Remark |

| 1 | When MLH<MLL,there is a delay of 10*(MLL-MLH) seconds on lp switch. Eventual pumpdown restart is over MLH+1 bar. |

| 2 | Fixed time 120 s and manual reset. |

| 3 | In H425V3, starting from revision 03, when MU1 and MU3 are 5.0 and b4A and b6A are oFF, use 5NTC controller for compressors without oil pump; connect HP probe on AN-6 and LP on AN-7. |

| 4 | Caution! Selection by manual override forces compressor to run whatever the high and low pressure; no safety is left except hardware ones. In slave mode the output is used for partialization. In kriwan mode output is off for reset during stand-by. |

| 5 | Caution! The external override drives the compressors ignoring high and low pressure; no safety is left except hardware ones. It is recommended to close this contact passing through both contacts of a low pressure and high pressure switch like a kp15. The closed contact is interpreted as "load" while the open contact is neutral. The delays dF4 through dF6 are respected. |

| 6 | After the delay elapsed, the override forces a load. Automatic reset. |

| 7 | When speed regulation is off the fan is operated on-off. |

| 8 | Caution! Speed regulation can cause fan fault or electronic board fault. Low and average minimum speed can increase the risk. |

| 9 | During the first 10 seconds of speed regulation, the n1L is replaced by (n1H+n1L)/2. |

| 10 | Passing from stand-by to on and at power on, there is a 5 second delay spent in a virtual stand-by. |

| 11 | The minus sign on display ("-") signals that output is going to start after a delay. |

| Display |

Alarm |

| A01 | mc 1 alarm | Pressure switch, thermistors, or any other compressor safety device has disconnected. |

| A02 | mc 2 alarm | Pressure switch, thermistors, or any other compressor safety device has disconnected. |

| A03 | mc 3 alarm | Pressure switch, thermistors, or any other compressor safety device has disconnected. |

| A04 | external override | The external override contact is driving the controller. |

| A05 | mc phase | Compressor overload/thermal relay disconnected, or missing mains phase - manual reset. |

| A06 | mc 1 oil pressure | Oil differential pressure remained under minimum value for 120 seconds - manual reset. |

| A07 | mc 2 oil pressure | Oil differential pressure remained under minimum value for 120 seconds - manual reset. |

| A08 | mc 3 oil pressure | Oil differential pressure remained under minimum value for 120 seconds - manual reset. |

| How to ... |

Function |

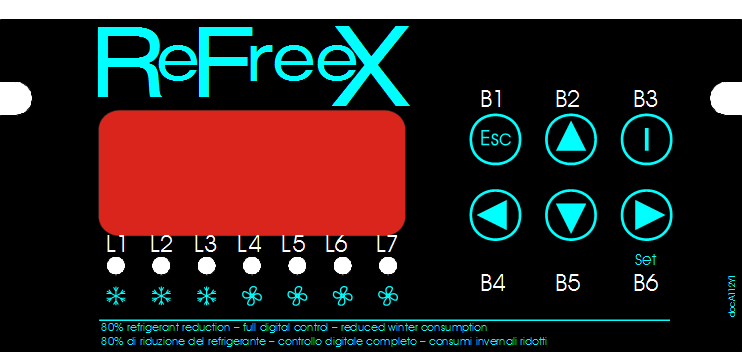

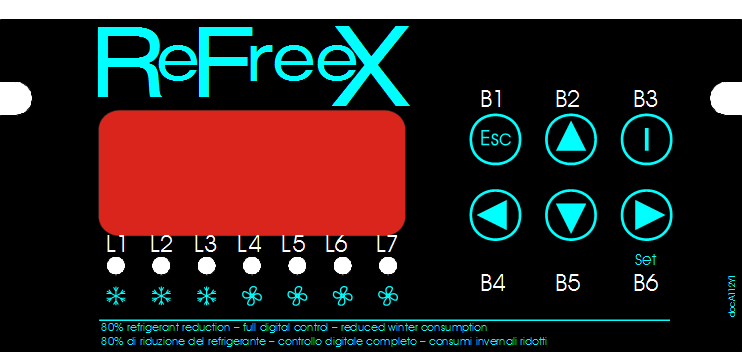

| Switch between on and stand-by. | Keep pressed B3 button, to activate and deactivate stand-by. In stand-by every output is, leds from L1 to L7 blink, timers continue to count. |

| Program the menu. | Keep pressed B6 to enter the menu. Navigate up and down with B2 and B5. Select the submenu by B6. Change the parameter by B2 and B5, press B6 to confirm, or B4 to go back without saving. The changes will have effect after the exit from programming pressing B4 repeatedly. Press B1 to exit immediately without saving any parameter. |

| Show or change pressure set. | Press shortly B6 - the display shows the current set point - change it by B2 and B5, and confirm it by B6. As alternative, enter the menu program as explained above, modify the parameter ML0, then confirm it. |